Solutions

Customer: Highway Materials

Location: King of Prussia, PA

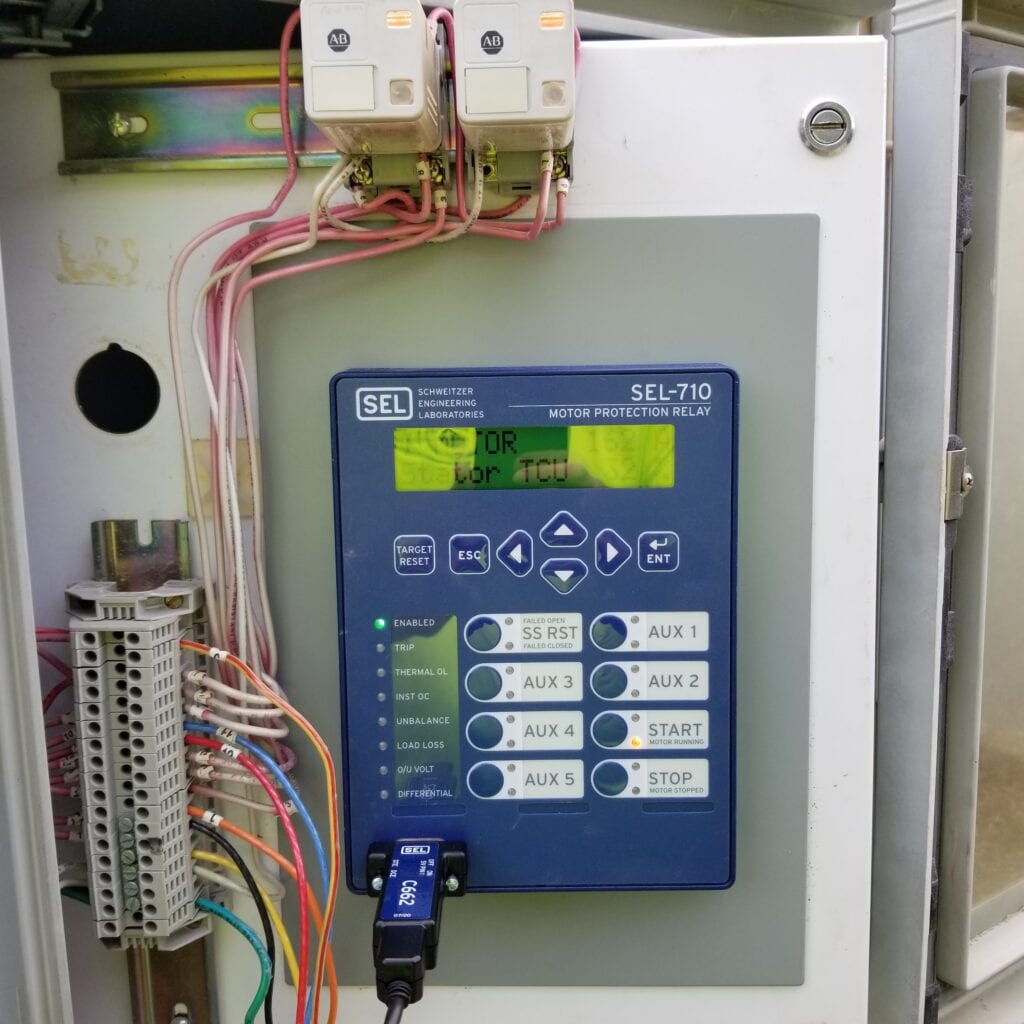

SSL was contacted about an existing installation of reduce voltage auto transformers used to start dewatering pumps at a local quarry. One of the existing motors had failed and it was determined that the existing motor protection relay was not providing the protection required from the existing RTD’s. SSL met with the customer regarding possible solutions and SSL recommended upgrading the existing motor protection relay to a new SEL-710 relay with RTD monitoring. SSL recorded the existing motor parameters and set the new relays based on the applicable motor protection parameters. SSL was onsite to test the system and verify proper operation of the relay and trip circuit. Both pumps are successfully operating.

Highway Materials

Customer: BJ Baldwin

Location: Morgantown, PA

SSL was contacted to provide suggestions to safely open and close switches remotely on several existing Pringle switches. After reviewing the installation, SSL made the suggestion to remove the existing mechanically operated Pringle switches and replace with new electrically operated molded case switches. Working with two of its partners, SSL provided a retrofit disconnect switch mounted on a back panel by Park Detroit, and a remote “Open / Close” pendant provided by Remote Solutions to safely operate the switch up to 50 feet away. Working in conjunction with BJ Baldwin, the system was installed on site. SSL provided the control wiring and was on site to test and demonstrate the operation of the system.

Timet Steel

Customer: Willier Electric Motor

Location: Wilmington, DE

SSL was contacted to provide equipment and services on an existing pumping station in Wilmington, DE. The pumping station was being converted from a 2300V station to a 460V station. The scope of work included providing new distribution equipment and motor controls as well as providing a system arc flash short circuit and coordination study and commissioning of the motor controls. SSL provided the data collection for the study and provided technical support to the customer thru out the project. The commissioning included providing relay settings on new Multilin 869 relays for both the new RVSS and new VFD. SSL completed the study, data collection, equipment supply, and commissioning on time and provided support during plant start up.

Wills Pumping Station

Customer: IB Abel Inc. & Schaedler Yesco Distribution

Location: Bainsbridge, PA

SSL had the opportunity to pursue a project located in our own backyard for Perdue AgriBusiness’ planned soybean processing facility in Conoy Township, Lancaster County, PA. After successfully bidding the project we assisted the design engineer, Sharpe Engineering, with some redesigns that helped shrink the size of the substation by 24’ in depth and 48’ in width by changing the orientation of the substation reducing the amount of structures required. The project included packaged substation equipment by DisTran Packaged Substations, (1) 69kV dead tank circuit breaker by Siemens, (1) 7.5MVA power transformer by Virginia Transformer Corporation, and (1) 15kV switchgear lineup with substation protective relays and backup battery system close coupled to the secondary of the transformer by Park Detroit. SSL managed the project to ensure that all onsite requirements were met, and confirm that all equipment would correctly match in the field, specifically the connection between the 15kV switchgear and secondary side of the transformer. The entire project was completed in September 2017 and is currently operational.

Perdue Soybean Processing Facility

Customer: Miller Bros. Electrical Contractors & New Jersey Resources

Location: Somerset County, PA

SSL was approached by Miller Bros. on a Friday afternoon to provide a proposal to supply the equipment and engineering services for a collector substation on a wind farm project in Western Pennsylvania. The end customer, New Jersey Resources, was currently over budget on the project and would have to put the project on hold if they could not reduce the cost. There were two challenges we had to meet in the proposal stage; we didn’t know what price point we had to hit to help the project move forward and the proposal was due the following Monday. With only 72 hours to put together a comprehensive proposal to provide engineering services and equipment, we stepped up to the challenge and had our submission complete by Monday. In addition to providing engineering services and equipment, SSL took on responsibility of coordinating between 16 different parties to ensure an efficient and on time project. The project was completed in late 2016, and is currently operational.

Ringer Hill Wind Farm

Customer: Gettle

Location: Waco, TX

SSL was contacted to discuss options on an upcoming substation design build project for Lehigh Cement. Several factors were considered on the project and different options were presented each with different advantages / disadvantages. A skidded substation concept was chosen to provide a unit that could be rolled into place to minimize the outage, provide one skid with the transformer and switchgear, allow Lehigh to test the substation prior to energization, and provide the customer with integral oil containment.

A team was constructed consisting of Gettle (electrical contractor), Lehigh Cement, M+S (engineer),SSL, ESS Metron, Benshaw, and Virginia Transformer for this project. SSL coordinated weekly project meetings and worked with all parties to deliver a successful project on time. The substation was energized in December 2017.

Waco Texas Substation

Customer: MC Dean

Location: Washington, DC

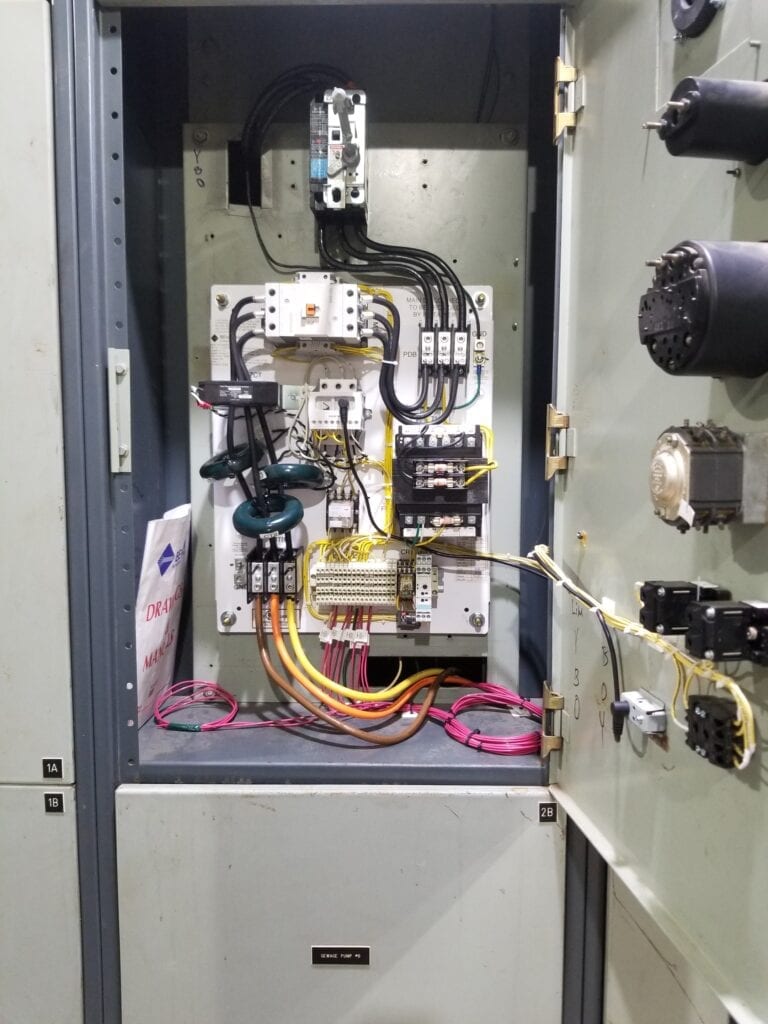

SSL was contacted by MC Dean to provide suggestions and solutions for an existing motor control center for DC Water located underground in downtown Washington DC. The existing MCC had been out of service for many years and the controls were obsolete. It was desired to keep the existing MCC structure, but replace the main, tie, main as well as the feeder breakers for 4 pumps. A tight schedule was required to bring the pump station back online in 3 months.

SSL worked onsite to make measurements of the existing gear and review the required interface with the new control system that was being added onsite. SSL designed a new control schematic for the existing pump starters. These pump starters were built by one of its partners, Benshaw to the specified dimensions and required cable lengths to fit into the existing MCC section. SSL also worked with another partner – Park Detroit to provide retrofit breakers to upgrade the main and tie breakers. An outage was taken to perform all work on schedule. The control wire was completely replaced by SSL, all breakers and breaker handles were replaced. Finally a system startup was performed to test the control logic, DRLO the existing bus, and startup all pumps. The project was completed on time in August 2018.

DC Water – 3rd and Constitution Avenue

Customer: SEPTA

Location: Philadelphia, PA

SEPTA South Substation, a company in South Philadelphia, contacted us about a new project for a skidded Substation. SEPTA needed this substation to provide power to charge 25 new electric buses. This substation was needed in less than three months to meet their installation schedule and arrival time for these new buses. SSL visited the site to perform an assessment to help determine proper sizing, location, and dimensions for the new substation. SSL coordinated a skidded substation provided by ESS Metron to meet the tight delivery schedule and to meet the utility requirements. The substation has been delivered and is awaiting the arrival of the new electric buses.

SEPTA South Substation

Customer: Techmer /Willier Electric

Location: New Castle, DE

SSL was contacted by Techmer in DE, about their incoming utility transformer that was being overloaded. SSL reviewed the application with the local utility as well as with Techmer’s engineering department to determine the cause of the problem. It was noted that due to the significant motor load feeding from the transformer, and the significant AC and DC drive load, that the overall power factor for the system was hovering between .65 and .75.

SSL worked with Power Survey, who specializes in power quality solutions. We reviewed the previous utility bills and discussed plans for any future expansion. Based on the conversations and analysis, a 600 kVAR automatic power factor correction bank was chosen for the application with steps in increments of 50kVAR. Since the system had significant non-linear loads (such as DC drives and AC drives), SSL worked to size a power factor correction bank that was detuned to the 3.78thharmonic. By detuning the PFCC bank, the system will avoid any possible resonance or overheating. The power factor correction bank was installed in August 2017, and the power factor has improved to .97 or greater.

Techmer PFCC

Customer: Graybar / Veolia Water

Location: Wilmington, DE

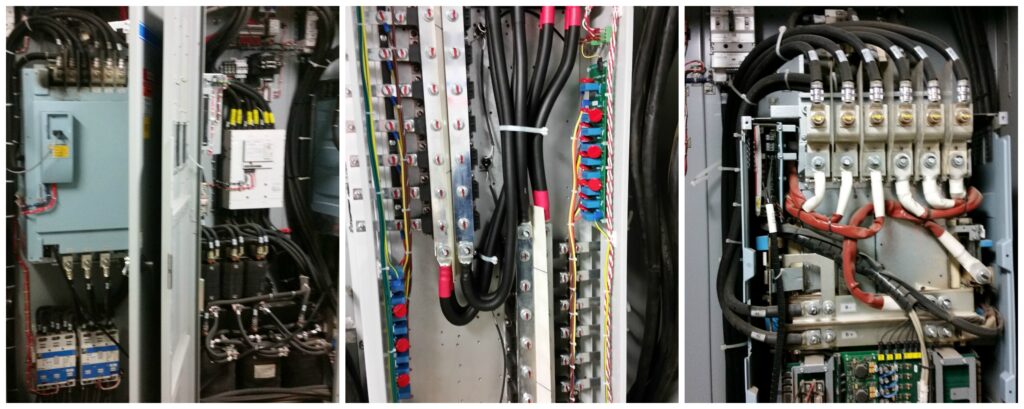

Veolia has existing full voltage starters installed for many years. These control blowers in their waste water facility. They have had recent issues with motor failures and maintenance issues on the driven equipment, so the suggestion was made to upgrade to an RVSS. The existing controls had been modified several times over the last 40 years. SSL visited the site to perform an assessment of the existing controls as well as determine the proper sizing and mounting locations for the new RVSS. The RVSS system was designed to fit into the existing space and utilize much of the existing, wiring, and controls. SSL also removed and cleaned up any wiring that was unnecessary or no longer in use, to provide ease in future troubleshooting. The system was upgraded in less than a month and is currently operational.

Veolia Water RVSS Upgrade

Customer: Aqua Water

Location: Neshaminy, PA

Aqua Water recently had a plant expansion for its Neshaminy plant. This plant expansion required the addition of (2) 2750 kVA substation transformers. SSL received the inquiry and worked with our partner, Virginia Transformer, to select the proper transformers, rating, efficiency level and transformer configuration. The project had a short leadtime, which required an expedited shipping schedule to meet the customer’s requirements. The project scope called for a substation style transformer with a nitrogen preservation system. The decision to go with Virginia Transformer as the transformer provider was easy as Virginia Transformer could meet the customer’s delivery schedule. SSL provided an onsite scope review with the customer prior to placing the order and helped with the onboard drawing review to meet the expedited shipping schedule. Finally, SSL was onsite to observe the offloading of the (2) transformers.

Neshaminy Water Treatment Plant

Customer: Team Service

Location: Baltimore, MD

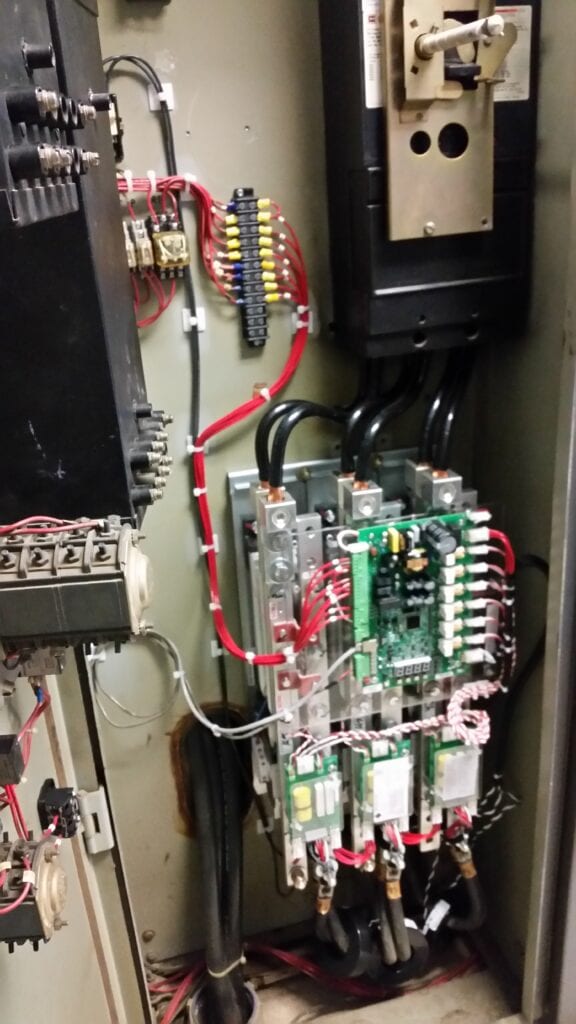

Baltimore City installed (4) low voltage clean power VFD’s. These were custom 18 pulse VFD’s which utilized (2) 18 pulse transformers and (2) 400 HP VFD’s operating in parallel. The VFD’s had a failure one evening and the original manufacturer was not willing to service without having the VFD’s sent back to the factory. Team Service contacted SSL to look at the existing application and make suggestions to the design. SSL visityed the site with Team Service and performed a comprehensive review of the existing application. SSL worked with Benshaw to provide a more reliable solution, while utilizing some of the existing components of the original VFD. It was determined that a better solution would be to remove the existing (2) paralleled VFD’s and replace the system with a new 18 pulse rectifier and a new 800 HP VFD for the application. The VFD system was designed to fit into the existing space and utilized much of the existing, wiring, controls, and cooling.

Jones Falls Pumping Station

Customer: Team Service / CSX

Location: Baltimore, MD

We were contacted by Team Service and CSX to review an existing switchgear line up at the Curtis Bay Pier location. The existing gear was 1950’s vintage gear utilizing GE Magna Blast vertical lift breakers. Using a collaborative approach, SSL presented several solutions, including gear replacement and refurbishing the existing gear. After reviewing all options, the team decided to upgrade the existing gear. This would eliminate the need for costly removal of existing gear, permitting, and heavy rigging while allowing for a quicker time for completion. After receiving the notice to proceed a complete gear inspection was completed, identifying the existing controls, site specific measurements, and condition of existing components. SSL worked with our partner AETA to provide (5) new relay panels with SEL relays to replace the existing controls, along with generating a complete set of new schematics. SSL integrated retrofit vertical lift breakers to replace the existing Magna Blast breakers, refurbished the existing lifting motors and lifting elevators and performed the installation over the July 4thshutdown. The project was completed in July of 2016.

CSX Switchgear Upgrades

Customer: IB Abel, Inc. & Schaedler Yesco Distribution

Location: York, PA

We were contacted by a number of local electrical contractors to supply the components in a 115KV substation for Johnson Controls’ new testing facility in York, PA. After reviewing the bid documents, we found that this opportunity meshed well with our strengths. We put together a comprehensive scope letter followed by a detailed bill of material highlighting the responsibilities each of our manufacturers would cover. Our scope of work included substation engineering services by ARM EnerTech, packaged substation equipment (including steel structures, prefabricated bus, gang operated switches, surge arresters, insulators, & foundation design) by DisTran Packaged Substations, (2) SF6 circuit breakers by Siemens, (2) 10/11.2/12.5/14MVA transformers by CG Power Systems, and 15KV switchgear housed inside a Power Distribution Center by ESS Metron. After multiple productive follow up meetings with the awarded contractor, IB Abel, we were successful in securing orders for each manufacturer involved. The project was completed in mid-2016.

Johnson Controls 115KV Substation

Customer: IETC

Location: Perryman, MD (Harford County)

The Sod Run Wastewater Treatment Plant (WWTP) in Perryman, MD had a problem. The existing dry type transformer needed to be replaced with a more efficient, liquid filled transformer. Due to the decreased size of the new liquid filled transformer, the engineer recommended that they move the existing service conduits, demolish the existing concrete pad, and pour a new pad. SSL had a better solution. After actively pursuing this project by bidding it to several contractors, SSL was given the order. Following a consultation with IETC, SSL and CG Power Systems came up with a transformer design featuring custom Air Terminal Cabinets (ATCs). This unique design meant that the existing service and concrete pad could be utilized “as-is” resulting in substantial savings in both cost and time. Officials at Harford County liked their tailor-made solution so much that they decided to have a second transformer manufactured in order to upgrade another transformer on the site. After installation of the transformers was completed, SSL provided manufacturer authorized field service including an installation inspection and post inspection report.

Sod Run WWTP Substation

Customer: Southern Contracting Corporation

Location: City of Industry, CA

One of our manufacturers asked us for assistance in a project outside of our territory. After reviewing the scope of the project, we decided not only to pursue a portion of the project through a single avenue but to cover every base and go ‘all in’. With no contacts and no knowledge of the Los Angeles County local market, we decided that our expertise on the products and interconnections of this complex project would position us to lend great value to the project bidders. We were successful in securing orders for our manufacturers on the electrical equipment and currently are working with Southern Contracting to support this project with our project management team. The scope of our product offering on this particular project includes the following: structures, group operated switches, surge arresters, insulators, aerial bus and connections, and grounding by DisTran Packaged Substations; SF6 dead tank circuit breakers, 40MVA power transformers, and station power liquid filled padmount transformers by CG Power Systems USA; 15KV metal-clad switchgear in power distribution centers (PDCs) with a SCADA integration substation system utilizing Schweitzer relays by ESS Metron; 15KV non-segregated busway tie between PDCs by Park Detroit. SSL continues to manage all expectations and points of ownership between our participating manufacturers, thereby providing Southern Contracting with a single point of contact for any questions that arise. Final energization was complete in July 2014.